diffusion/time_heat_equation_multi_material.py¶

Description

Transient heat equation with time-dependent source term, three different material domains and Newton type boundary condition loss term.

Description¶

This example is inspired by the Laser Powder Bed Fusion additive manufacturing process. A laser source deposits a flux on a circular surface (a full layer of the cylinder being built) at regular time intervals. The heat propagates into the build plate and to the sides of the cylinder into powder which is relatively bad at conductiong heat. Heat losses through Newton type heat exchange occur both at the surface where the heat is being deposited and at the bottom plate.

The PDE for this physical process implies to find  for

for ![x

\in \Omega, t \in [0, t_{\rm final}]](../_images/math/fbb28adc8f39a717ada80aa6a3e4014d59fc07f2.png) such that:

such that:

![\left\lbrace

\begin{aligned}

\rho(x)c_p(x)\frac{\partial T}{\partial t}(x, t)

= -\nabla \cdot \left( -k(x) \underline{\nabla} T(x, t) \right) &&

\forall x \in \Omega, \forall t \in [0, T_{max}] \\

-k \underline{\nabla} T(x, t)\cdot \underline{n}

= q(t)+h(T-T_\infty) && \forall x \in \Gamma_{source} \\

-k \underline{\nabla} T(x, t)\cdot \underline{n}

= q(t)+h(T-T_\infty) && \forall x \in \Gamma_{plate} \\

\underline{\nabla} T(x, t)\cdot \underline{n}

= 0 && \forall x \in \Gamma \setminus(\Gamma_{source}

\cap\Gamma_{plate})

\end{aligned}

\right.](../_images/math/bf802c0b90cd721798a11adb99f4864792eba506.png)

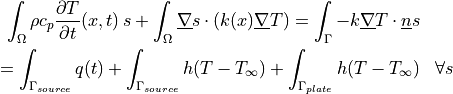

The weak formulation solved using sfepy is to find a discretized field

that satisfies:

that satisfies:

Uniform initial conditions are used as a starting point of the simulation.

Usage examples¶

The script can be run with:

sfepy-run sfepy/examples/diffusion/time_heat_equation_multi_material.py

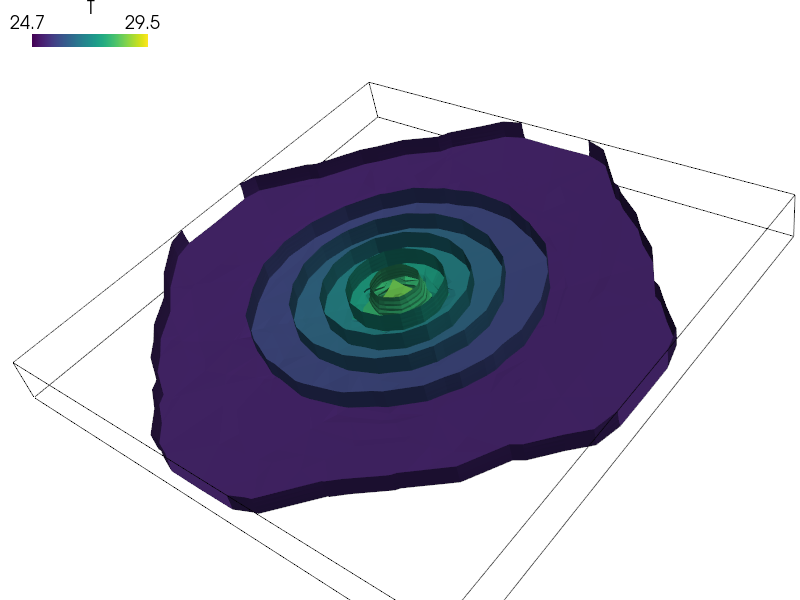

The last time-step result field can then be visualized as isosurfaces with:

sfepy-view multi_material_cylinder_plate.119.vtk -i 10 -l

The resulting time evolution of temperatures is saved as an image file in the output directory (heat_probe_time_evolution.png).

This script uses SI units (meters, kilograms, Joules…) except for temperature, which is expressed in degrees Celsius.

r"""

Transient heat equation with time-dependent source term, three different

material domains and Newton type boundary condition loss term.

Description

-----------

This example is inspired by the Laser Powder Bed Fusion additive manufacturing

process. A laser source deposits a flux on a circular surface (a full layer of

the cylinder being built) at regular time intervals. The heat propagates into

the build plate and to the sides of the cylinder into powder which is

relatively bad at conductiong heat. Heat losses through Newton type heat

exchange occur both at the surface where the heat is being deposited and at the

bottom plate.

The PDE for this physical process implies to find :math:`T(x, t)` for :math:`x

\in \Omega, t \in [0, t_{\rm final}]` such that:

.. math::

\left\lbrace

\begin{aligned}

\rho(x)c_p(x)\frac{\partial T}{\partial t}(x, t)

= -\nabla \cdot \left( -k(x) \underline{\nabla} T(x, t) \right) &&

\forall x \in \Omega, \forall t \in [0, T_{max}] \\

-k \underline{\nabla} T(x, t)\cdot \underline{n}

= q(t)+h(T-T_\infty) && \forall x \in \Gamma_{source} \\

-k \underline{\nabla} T(x, t)\cdot \underline{n}

= q(t)+h(T-T_\infty) && \forall x \in \Gamma_{plate} \\

\underline{\nabla} T(x, t)\cdot \underline{n}

= 0 && \forall x \in \Gamma \setminus(\Gamma_{source}

\cap\Gamma_{plate})

\end{aligned}

\right.

The weak formulation solved using `sfepy` is to find a discretized field

:math:`T` that satisfies:

.. math::

\begin{aligned}

\int_\Omega\rho c_p \frac{\partial T}{\partial t}(x, t) \, s

+ \int_\Omega \underline{\nabla} s \cdot (k(x)

\underline{\nabla}

T) = \int_\Gamma -k \underline{\nabla} T \cdot \underline{n} s \\

= \int_{\Gamma_{source}} q(t) +

\int_{\Gamma_{source}} h(T-T_\infty)

+ \int_{\Gamma_{plate}} h(T-T_\infty) && \forall s

\end{aligned}

Uniform initial conditions are used as a starting point of the simulation.

Usage examples

--------------

The script can be run with::

sfepy-run sfepy/examples/diffusion/time_heat_equation_multi_material.py

The last time-step result field can then be visualized as isosurfaces with::

sfepy-view multi_material_cylinder_plate.119.vtk -i 10 -l

The resulting time evolution of temperatures is saved as an image file in the

output directory (heat_probe_time_evolution.png).

This script uses SI units (meters, kilograms, Joules...) except for

temperature, which is expressed in degrees Celsius.

"""

import numpy as nm

from sfepy import data_dir

from sfepy.discrete.probes import LineProbe

import matplotlib.pyplot as plt

import os

nominal_heat_flux = 6.36e5

alpha = 0.25

t_start = nm.array([0., 20., 40.]) # times when heating starts (seconds)

t_stop = nm.array([10., 30., 50.]) # times when heating stops (seconds)

T0 = 25. # °C

h = 50. # W/m2/K

mm = 1e-3

filename_mesh = data_dir + '/meshes/3d/multi_material_cylinder_plate.vtk'

materials = {

'powder': ({'lam': 0.16,

'rho_cp': 1330. * 650.},),

'cylinder': ({'lam': 153.,

'rho_cp': 2760. * 935.,

'lam_vec': 173. * nm.eye(3)},),

'plate': ({'lam': 153.,

'rho_cp': 2660. * 927.,

'lam_vec': 153. * nm.eye(3)},),

'heat_flux_defined_by_func': 'get_flux_value',

'heat_loss': ({'h_bot': -h, 'T_bot_inf': T0,

'h_top': -h, 'T_top_inf': T0},)

}

regions = {

'Omega': 'all',

'Omega_Cylinder': 'cells of group 4',

'Omega_Powder': 'cells of group 3',

'Omega_Plate': 'cells of group 1 +v cells of group 2',

'Gamma_Plate': ('vertices in (z < -9.95e-3)', 'facet'),

'Gamma_Source': ('vertices of surface *v r.Omega_Cylinder', 'face'),

}

def get_flux_value(ts, coors, mode=None, **kwargs):

"""Defines heat flux as a function of time."""

if mode == 'qp':

shape = (coors.shape[0], 1, 1)

if nm.any((ts.time >= t_start) & (ts.time <= t_stop)):

flux = alpha * nominal_heat_flux

else:

flux = 0.

val = flux * nm.ones(shape, dtype=nm.float64)

return {'val': val}

functions = {

'get_flux_value': (get_flux_value,),

}

fields = {

'temperature': ('real', 1, 'Omega', 1),

}

variables = {

'T': ('unknown field', 'temperature', 1, 1), # 1 means history=1

's': ('test field', 'temperature', 'T'),

}

ebcs = {

}

integrals = {

'i': 2

}

equations = {

'Temperature': """

dw_dot.i.Omega_Cylinder(cylinder.rho_cp, s, dT/dt )

+ dw_dot.i.Omega_Plate(plate.rho_cp, s, dT/dt )

+ dw_dot.i.Omega_Powder(powder.rho_cp, s, dT/dt )

+ dw_laplace.i.Omega_Cylinder(cylinder.lam, s, T)

+ dw_laplace.i.Omega_Plate(plate.lam, s, T)

+ dw_laplace.i.Omega_Powder(powder.lam, s, T)

= dw_integrate.i.Gamma_Source(heat_flux_defined_by_func.val, s)

+ dw_bc_newton.i.Gamma_Source(heat_loss.h_top, heat_loss.T_top_inf, s, T)

+ dw_bc_newton.i.Gamma_Plate(heat_loss.h_bot, heat_loss.T_bot_inf, s, T)

"""

}

ics = {

'ic1': ('Omega_Powder', {'T.0': T0}),

'ic2': ('Omega_Plate', {'T.0': T0}),

'ic3': ('Omega_Cylinder', {'T.0': T0}),

}

def gen_probe():

"""Instantiates a line probe used later by the `step_hook` function."""

p0, p1 = nm.array([0., 0., -10. * mm]), nm.array([0.0, 0.0, 15. * mm])

line_probe = LineProbe(p0, p1, n_point=100, share_geometry=True)

return line_probe

line_probe = gen_probe()

# inits an empty list that will hold the probe results

probe_results = []

def step_hook(pb, ts, variables):

"""

This implements a function that gets called at every step from the

time-solver.

"""

T_field = pb.get_variables()['T']

pars, vals = line_probe(T_field)

probe_results.append(vals)

def post_process_hook(out, pb, state, extend=False):

ts = pb.ts

if ts.step == ts.n_step - 1:

fig, (ax1, ax2) = plt.subplots(nrows=2)

temperature_image = nm.array(probe_results).squeeze()

m = ax1.imshow(temperature_image.T, origin='lower', aspect='auto')

ax1.set_xlabel("time step")

ax1.set_ylabel("distance across build\nplate and cylinder")

fig.colorbar(m, ax=ax1, label="temperature")

ax2.plot(temperature_image.T[0], label="bottom")

ax2.plot(temperature_image.T[-1], label="top")

ax2.set_xlabel("time step")

ax2.set_ylabel("temperature (°C)")

ax2.legend()

fig.tight_layout()

fig.savefig(os.path.join(pb.output_dir, 'heat_probe_time_evolution.png'),

bbox_inches='tight')

return out

solvers = {

'ls': ('ls.auto_direct', {

# Reuse the factorized linear system from the first time step.

'use_presolve': True,

# Speed up the above by omitting the matrix digest check used normally

# for verification that the current matrix corresponds to the

# factorized matrix stored in the solver instance. Use with care!

'use_mtx_digest': False,

}),

'newton': ('nls.newton', {

'i_max': 1,

'eps_a': 1e-5,

'is_linear': True,

}),

'ts': ('ts.simple', {

't0': 0.0,

't1': 60.,

'dt': None,

'n_step': 120,

'verbose': True,

'is_linear': True,

}),

}

options = {

'step_hook': 'step_hook',

'post_process_hook': 'post_process_hook',

}